WhatsApp/WeChat:

+86 18994470782

+86 18994319892

E-mail:

laserhy@126.com

Jeanyjin@laserhy.com

Address:

Building 14, No.399 Gongtang Road, Luzhi Town, Wuzhong District, Suzhou, Jiangsu, CHINA (215127)

The optical fiber laser marking machine has high electro-optical transfer efficiency and adopts air cooling. The whole machine is small in size, good in output light speed quality and high in reliability.

Features and advantages:

Optical fiber laser engraving has lower cost, higher flexibility, environmental protection, compare with the traditional method, such as mechanical engraving, chemical corrosion, screen printing, ink printing, etc.

1.Non-contact marking: Laser marking is processed to non-mechanical "knife". It can mark any regular or irregular graph. And no internal stress produced during the marking, to protect the accuracy of the work-piece. No corrosion, no "tool" wear, no poison, no pollution. It’s also easy to control and operate by the computer system.

2.Excellent beam quality: small focusing spot, and better processing quality.

3.Low using cost: Power consumption is about 500W, and no consumables.

4.Low stop rate: lifetime of laser source is up to 100,000 hours.

5. Anti-fake: The typical characteristic is to make permanent mark with the laser beam. And the mark is not easy to imitate and change.

Comparison of markings

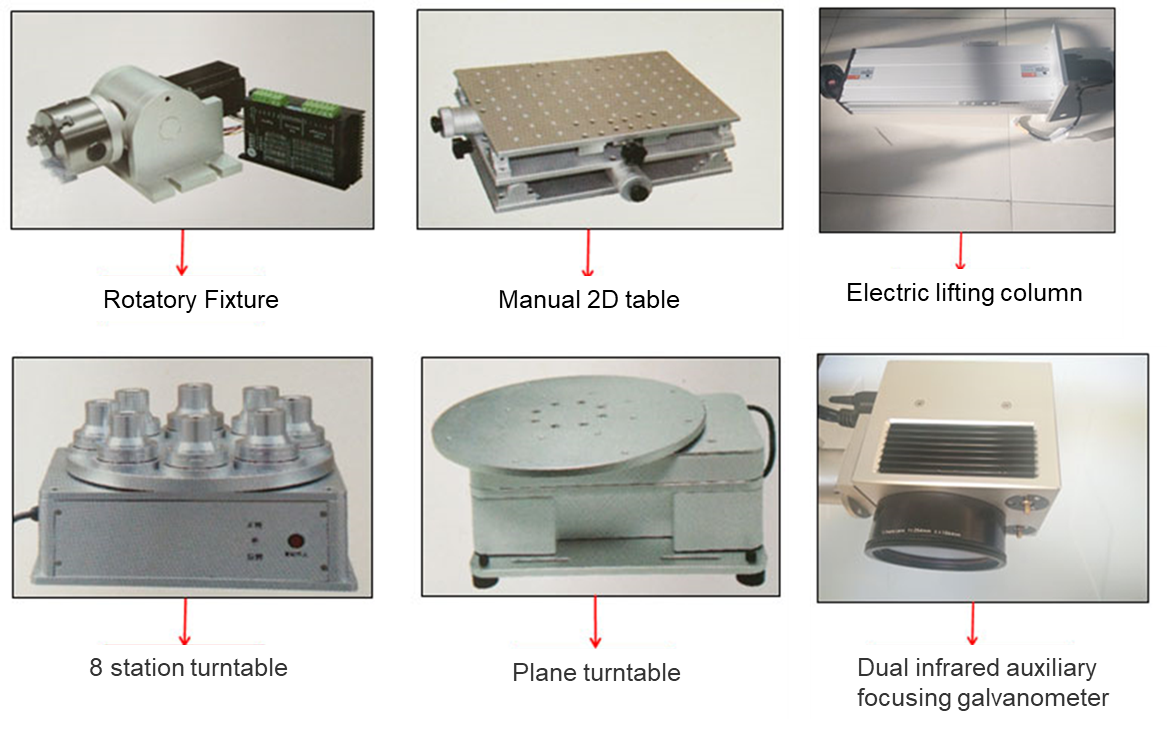

Optional accessories:

Model | HY-MFB01 |

Average output power | 20W/30W/50W/60W/100W/200W |

Laser wavelength | 1.06µm |

Laser frequency | 20-80kh or 50-100khz |

Standard engraving area | 110mm*110mm |

Optional engraving area | 70mm*70mm/800mm*800mm |

Min. Letter | 0.2mm |

Engraving depth | <=0.3mm |

Engraving line speed | <=7000mm/s |

Minimum line width | 0.01mm |

Repeatability | ±0.002mm |

Power supply | 220V/50Hz/60Hz |

Total Power consumption | 500W |

Application:

Applicable to all metal material, such as stainless steel, steel, copper, silver, gold, jewelry, aluminum alloy, mold, etc.

Suitable for non-metal: PVC, PE, ABS and other plastic product; Chip industry, Ceramic products.

Be applied to surface treatment fields: Anodic oxidation electroplating, paint, ink, CED, electroplating, and other surface marking logo or oxygen breaking conductive treatment.

Other application: Micro-pore processing, metal wire stripping and deep marking of metal materials.

Installation Environment Requirements

Prevent Vibration: A stable workplace is required.

Reduce dust: To protect the production quality, a clean workplace is needed to protect the precision electronic and optical components.

Grounding and Voltage: Laser marking machine requires a stable voltage which in accordance with the national standard strictly. A right and good grounding can ensure the machine work properly.