YAG optical fiber transmission laser welding machine is a kind of laser welding equipment that couples the high-energy laser beam into the optical fiber, after long-distance transmission, collimated it into parallel light through the collimator, and then focused on the work piece for welding. For parts that are difficult to be accessed by welding, flexible transmission non-contact welding has greater flexibility. The laser beam of optical fiber transmission laser welding machine can realize the light splitting in time and energy, and can process multiple beams at the same time, which provides conditions for more precise welding.

Flexible welding can be configured with 1-4 welding joints to realize multi station welding. The negative energy feedback system makes the output energy more uniform and the weld spot consistency better. It can be matched with platform type automatic welding, galvanometer type high-speed spot welding, robot automatic welding, mold repair welding workbench and hand-held welding joint.

Features and advantages:

-Capable for precision welding of 0.15mm metal sheet, and welding of hard-melt materialHigh quality optical lens, good beam quality, evenly energy.

- Optical fiber transmission output is adopted, with a fast welding speed, deeper weld, less deformation.

- Negative energy feedback technology is adopted to ensure the stability of welding quality.

-Unique design , it can realize multi work station time-sharing or simultaneous welding to improve the utilization rate of equipment.

Model | HY-WT01 |

Laser Power | 50-600 W |

Work Mode | Pulse |

Single Pulse Laser Energy | 10-100J |

Laser Wavelength | 1064 nm |

Pulse Width | 0.1-20ms |

Spectroscopy Model | Time / energy spectroscopy |

Optical Fiber Qty | 1-4 paths |

Standard Work Area | 300*200 mm(Customized) |

Power Supply | 220V&380V/50HZ&60HZ |

Max. Power consumption | 2-12KW |

Cooling Method | Water Chiller |

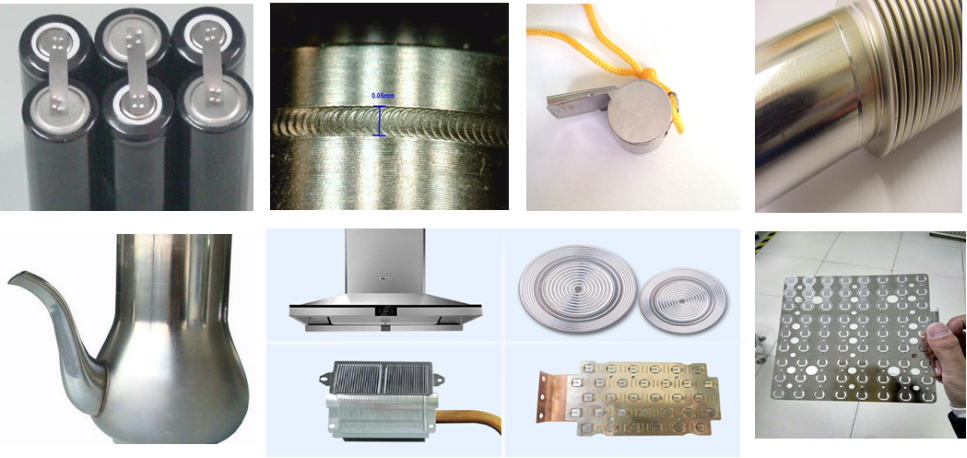

Application:

Widely used in precision welding, includes batteries, solar energy, mobile communication, optical communication devices, frames, mold, electronics, instruments, gold and silver jewelry, precision device, medical devices, sensors, aerospace components, automotive industry, motor industry, etc.