WhatsApp/WeChat:

+86 18994470782

+86 18994319892

E-mail:

laserhy@126.com

Jeanyjin@laserhy.com

Address:

Building 14, No.399 Gongtang Road, Luzhi Town, Wuzhong District, Suzhou, Jiangsu, CHINA (215127)

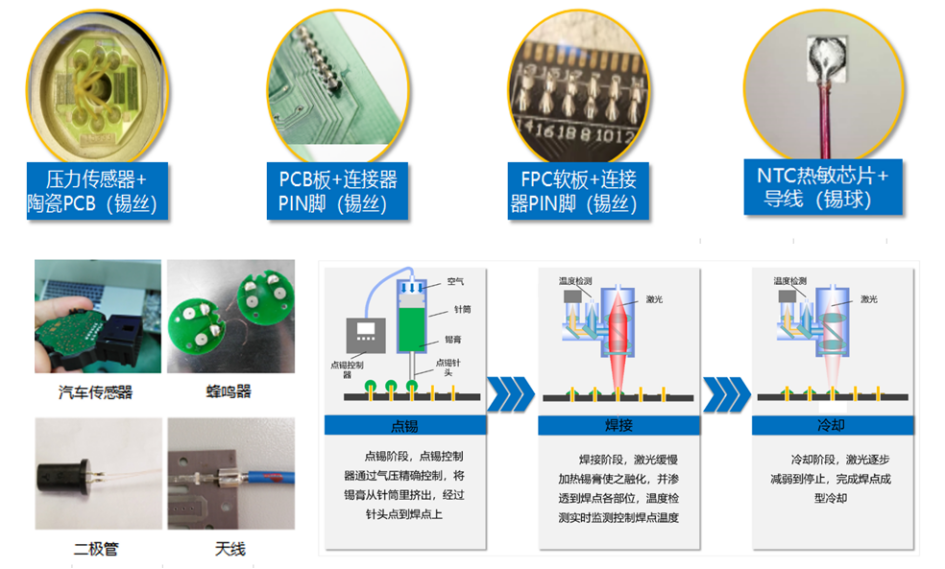

Laser tin welder is a kind of brazing method that uses laser as the heat source and melts tin to make the amendments close together.

The device adopts semiconductor laser, light-weight closed-loop design, and integrates high-precision constant temperature control system, CCD positioning system, motion mechanism, flexible workbench, etc.

It can be customized, flexibly configuration, and can realize non-contact welding.

Features and advantages:

Adopt semiconductor laser, integrate high-precision thermostatic control system, non-contact welding, and minimal heat affected zone.

It can cover micro precision welding to large solder joint welding, and the size of solder joint: φ 0.2mm-1.5mm.

Centralized heat input, controllable heat input, small heat impact, non-contact welding, easy to realize automatic welding.

It can replace manual electric soldering iron welding, so as to reduce the harm of volatile in the brazing process to the health of operators.

Model | HY-SW01 |

Work Mode | Continuous / Modulation |

Output Power(Continue) | 50W-70W-100W |

Wave Length | 915nm |

Power Stability (long term) | ±2% |

Power Stability (short term) | ±0.5% |

Output Power Adjustable Range | 0%-100% |

Power Supply | AC220V/50HZ |

Cooling Method | Air Cooling |

Work Environment | 15-35℃ |

Power Consumption | 500W |

Application:

It is used in the electronic industry, high-precision automatic welding of PCB circuit boards, optical components, acoustic components, semiconductor refrigeration components and other components of 3C electronic products, such as through-hole components, harness electronics, pin pins, etc.