WhatsApp/WeChat:

+86 18994470782

+86 18994319892

E-mail:

laserhy@126.com

Jeanyjin@laserhy.com

Address:

Building 14, No.399 Gongtang Road, Luzhi Town, Wuzhong District, Suzhou, Jiangsu, CHINA (215127)

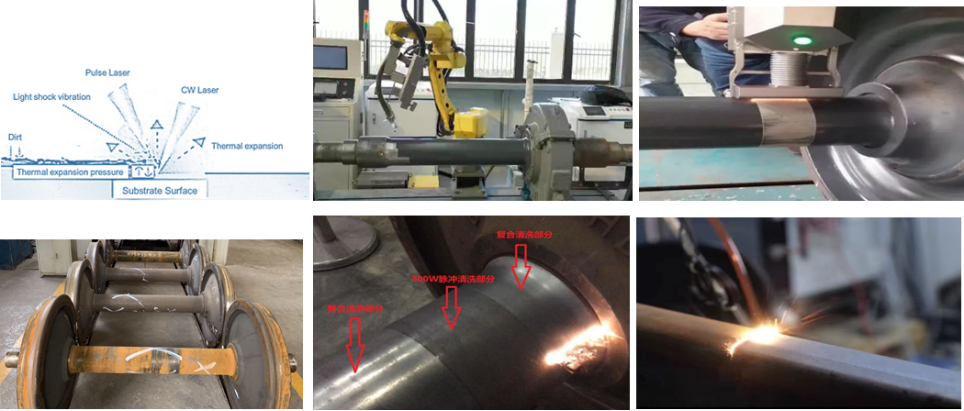

The principle of laser composite cleaning technology is apply semiconductor continuous laser as heat conduction output, make the adhesion absorbs energy, gasification and generates plasma cloud. Then the thermal expansion pressure between metal materials and adhesion is formed to reduce the adhesive force between the two layers.

When the high-energy pulse laser beam is output by the pulse laser, the vibration shock wave will separate the adhesion with weak adhesive force directly from the metal surface, so as to realize a rapid laser cleaning.

The feature of laser composite cleaning is that it combines the function of both continuous laser and pulse laser at the same time, and reshapes the output laser into a circular ring spot, high peak power pulse spot as the center, high power continuous spot as outer ring. This makes cleaning effect 1+1 > 2, so as to realize rapid laser cleaning.

Features and advantages:

Increase the cleaning efficiency by two to three times with the same price.

Improved cleaning quality, and can protect substrate from damaging.

Higher cleaning efficiency, and more stable cleaning process.

Model | HY-CT01 |

Laser Type | Circular ring spot Composite laser cleaning |

Max. Laser Power | 300W Pulse + 1500W Continuous |

Scan Speed | 5m/s |

Scan width | 10-100MM |

| 10m |

Cooling Method | Water Cooling |

Power Supply | 220V 50/60HZ |

Machine Net Weight | ≈150kg |

Application:

Laser composite cleaning machine is widely used in ship, automobile repair, plastic mold, high-end machinery, track, environmental protection and other industries, and can remove resin, paint, oil stain, stain, dirt, rust, coating, coating and oxide layer on the surface of objects.

Applied to the cleaning of thick coatings and attachments with strong adhesion.

Applied to laser cleaning of high reflective materials such as aluminum alloy.