WhatsApp/WeChat:

+86 18994470782

+86 18994319892

E-mail:

laserhy@126.com

Jeanyjin@laserhy.com

Address:

Building 14, No.399 Gongtang Road, Luzhi Town, Wuzhong District, Suzhou, Jiangsu, CHINA (215127)

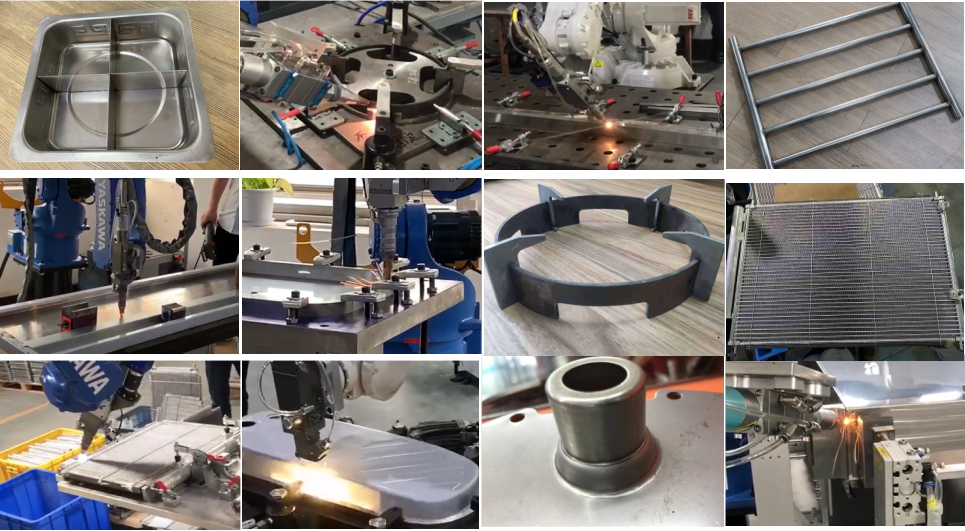

By using high-precision 6-axis robot with large arm, cooperating with the high-precision turnover positioner, the robot welding series can weld large-size, high-precision and complex parts. Configurated with different laser welding joints, it can make laser wire filling welding, spot welding, tailor welding and overlap welding. The control system adopts ABB control system with high industrial grade. It can work independently in a single station, or it can be integrated into the automatic production line. The workstation can be customized with single-layer or double-layer layout. It's widely applied in automobile manufacturing, rail transit, aerospace and other industries.

Characteristics:

1. It's simple and easy to handle, and do not need a traditional professional welder.

2. Do not need wear face mask instead of wear the laser protective goggles.

3. The weld seam is smooth with nice appearance, no grinding or only a little grinding.

4. By controlling the laser energy, the welding part only make tiny even no deformation.

5. Low use-cost. Low power consumption, low gas consumption and low lens consumption.

6. Applicable for welding large or long work pieces by using the long optical fiber up to 8-10 m.

7. Applicable to a variety of welding processes, including spot welding, seam welding and overlap welding.

8. Use program-controlled robot can weld sharp parts with specific routine.

Comparison between TIG and Laser welding:

Tig Welding | Laser Welding | |

Heat | Very high | Very low |

Deformation | Easy to deform | No deformation |

Processing time | Long | Short |

Welding Workload | 2 professional welders | 1 operator |

Exterior | Unsightly, need polishing | Smooth and beautiful, polishing free |

Welding spot | Large welding spot | Fine welding spot, adjustable |

Perforation | Easy to pierce | Not easy to perforate, controllable |

Protective gas | Need argon or N | Need argon or N |

Precision | General | Precision |

Power consumption | High | Low |

Safety | Ultraviolet light, radiation | Radiation-free |

Model | HY-WF01 | HY-WF01 | HY-WF01 | HY-WF01 |

Laser Power | 1000W | 1500W | 2000W | 3000W+ |

Welding depth (SS) | 2.68mm | 3.59mm | 4.57mm | 6.87mm+ |

Welding depth (CS) | 2.06mm | 2.77mm | 3.59mm | 4.79mm+ |

Welding depth (Al) | 2mm | 3mm | 4mm | 6mm+ |

Feeding Wires' Dimension | 0.8-1.2wire | 0.8-1.6 wire | 0.8-1.8 wire | 0.8-2.0 wire |

Laser Wavelength | 1070 +/-10 nm | 1070 +/-10 nm | ||

Laser Frequency | 50-5000HZ | 50-5000HZ | ||

Cooling Method | Water Chiller | Water Chiller | ||

Power Supply | 220V 50&60HZ | 380V /50&60HZ | ||

Tooling and fixture | Customized | Customized | ||

Robot (Optional) | ABB, YASKAWA(arm 1.4m,1.7m,2m), Chinese brand | |||

Application:

It is widely applied to many fields of mass production, such as 3C, medical devices, automobiles, railways, ships, aviation, air conditioning condensers, home decoration, elevators, power batteries, etc.